LED signs have become ubiquitous in our modern world, lighting up everything from cityscapes to sports arenas and retail storefronts. But have you ever wondered what goes into creating these vibrant, high-tech displays? Behind the dazzling visuals and impressive brightness lies a meticulous and skilled manufacturing process. Join us as we take a behind-the-scenes look at the craftsmanship and technical expertise involved in LED sign manufacturing.

1. Concept and Design

High-quality components are the cornerstone of reliable and long-lasting LED displays.

Key Components:

- LED Chips: The heart of the display, these chips determine brightness, color accuracy, and energy efficiency. High-quality chips ensure vivid visuals and long lifespans.

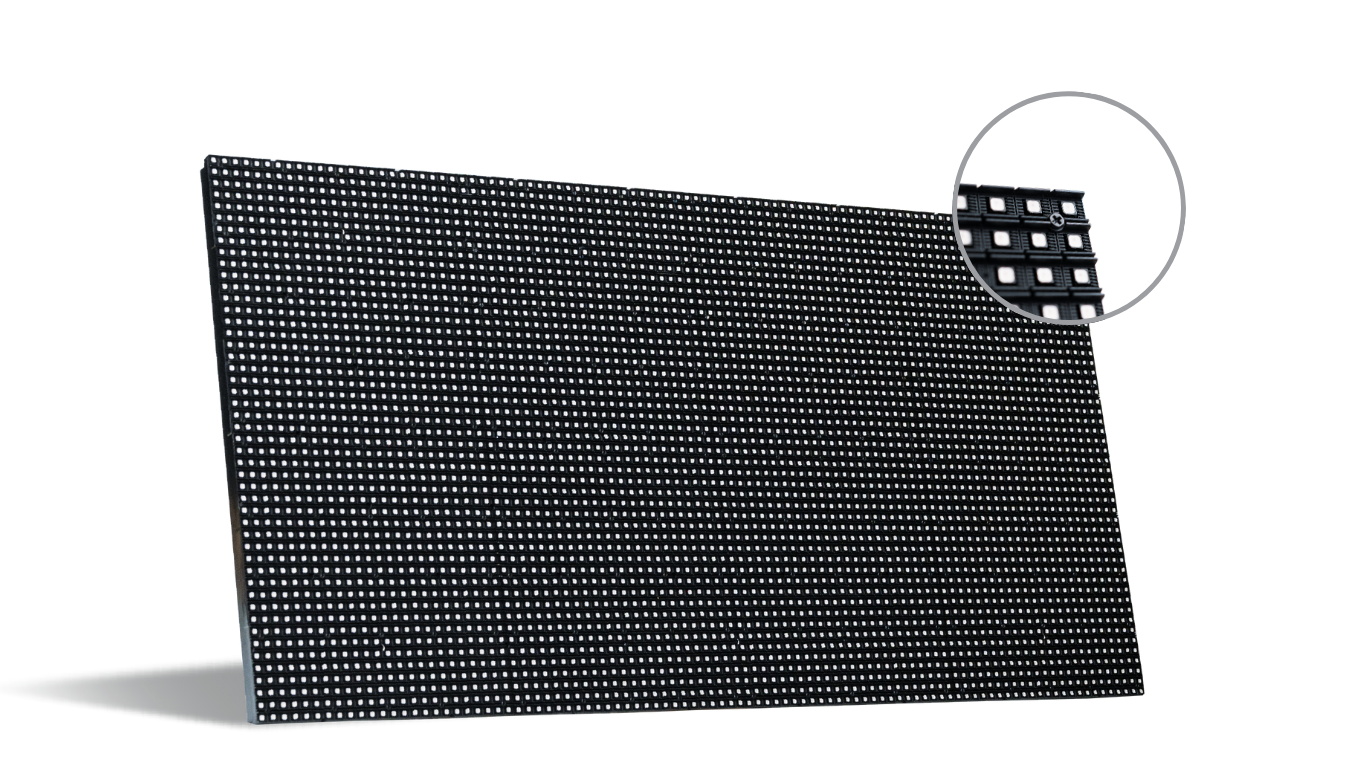

- Printed Circuit Boards (PCBs): The foundation of the display, PCBs connect and support the LED chips. Their design directly affects heat dissipation and overall reliability.

- Power Supplies and Controllers: Essential for maintaining brightness, managing color transitions, and ensuring smooth operation, these components are the brains behind the sign.

2. Component Selection

Every great LED sign project starts with an idea. This phase involves collaboration between designers and engineers to determine the specifications, layout, and functionality of the display. Key considerations include:

- Choosing the right LED technology, such as SMD (Surface-Mounted Device) or DIP (Dual Inline Package).

- Defining the resolution and size to match the client’s requirements.

- Designing the visual layout to optimize impact for specific applications like advertising, branding, or information displays.

3. Assembly and Construction

Bringing an LED sign to life requires precision and expertise:

- Mounting LED Chips: Advanced techniques, like reflow soldering, ensure LED chips are securely and accurately mounted onto the PCB.

- Panel Assembly: Modular panels are enclosed in protective housing, incorporating cooling systems to prevent overheating.

- Sealing and Weatherproofing: Outdoor LED displays undergo rigorous sealing processes to protect against rain, dust, and extreme temperatures, ensuring durability in harsh environments.

Quality Control: Ensuring Excellence

1. Testing and Calibration

Before leaving the factory, each LED sign is thoroughly tested to meet strict quality standards:

- Brightness and Color Calibration: Uniformity is essential to ensure consistent, vibrant visuals across the entire display.

- Functional Testing: Comprehensive tests identify and resolve potential issues like dead pixels or connectivity problems.

2. Reliability and Durability Testing

imulating real-world conditions guarantees long-term performance:

- Heat and Humidity Tests: Ensuring displays withstand extreme environmental conditions.

- Shock and Vibration Tests: Verifying structural integrity during transportation and installation.

Craftsmanship and Expertise

1. Precision Engineering

Manufacturing LED signage demands precision at every step. Skilled engineers meticulously assemble and test each component, ensuring the final product meets rigorous standards of quality.

2. Customization and Artistry

The artistry of LED signage lies in its ability to captivate. Designers and engineers collaborate to create stunning visual layouts, leveraging creative effects and intricate designs to deliver maximum impact.

The Future of LED Sign Manufacturing

As technology continues to evolve, the LED signage industry is pushing boundaries with:

- Higher Resolution Displays: Advanced LED chips are enabling ultra-high-definition visuals.

- Sustainability: Energy-efficient components are reducing power consumption, making LED displays more eco-friendly.

- Smart Technology Integration: Features like IoT connectivity and remote content management are enhancing interactivity and engagement.

Why Craftsmanship Matters in LED Sign Manufacturing

The process of creating an LED sign is a seamless blend of technical expertise, innovation, and artistic vision. From conceptual design and component selection to meticulous assembly and rigorous testing, every step ensures that the final display is as functional as it is visually stunning.

By combining precision engineering with creative artistry, manufacturers are delivering displays that light up cityscapes, captivate audiences, and set new standards for visual communication.